Learn about our collaboration with NASA and industry leaders in developing radiation-hardened, plastic packaging for space electronics, known as QML Class P, to power missions with size, weight and power in mind

As curiosity and innovation drive space exploration forward, constraints for size, weight and power continue to tighten. To design for space, you have little to no room for error. And increasing space exploration activities by public and private entities, whether in Earth’s orbit or way beyond, requires continued collaboration and improvements.

Recently, our company worked with NASA and other industry experts to lead the development of a new plastic packaging standard for space electronics, known as Qualified Manufacturers List Class P (QML Class P). Electronics in space must meet government standards set forth in the QML, ranging from radiation-tolerant or radiation-hardened devices in either ceramic or plastic packaging. The QML provides assurance that parts will operate as intended in the harsh environments of space.

“The QML Class P packaging standard enables more advanced computing in space, such as how satellites and other spacecraft can autonomously process data and make decisions in orbit as opposed to beaming data back down to Earth,” said Javier Valle, product line manager for space power at our company. “More processing capability also requires greater power. With TI’s QML Class P portfolio, we increase the efficiency of the power supply while reducing the size of the overall package, resulting in much higher power density.”

The QML exists with its many classes to ensure predictability in designs, meeting qualification and certification according to government standards, but new standards such as Class P are introduced as our knowledge and use cases advance. The QML Class P standard enables the use of radiation-hardened plastic packaging for power-management, processor, communications and high-speed integrated circuits (ICs) in satellites, rovers and other spacecraft.

Bring space up to speed through plastic

Ceramic packaging has often been the go-to, reliable option, as it meets a variety of government agency specifications in the United States. Manufacturers of ceramic-packaged space electronics have released ICs to the market under a qualification known as QML Class V.

Until QML Class P, there had been no standardized, radiation-hardened equivalent for plastic packaging.

Earlier forms of plastic packaging standards have also been especially vulnerable to a process known as outgassing. Outgassing describes a process when the harsh temperature and vacuum conditions of space vaporize organic compounds, which can deposit onto electronics causing them to fail. Depending on the severity, the effects of outgassing can interrupt or completely end missions.

Advancements in manufacturing and testing procedures have helped address the consequences of outgassing and other environmental concerns in space. However, these improvements can vary from manufacturer to manufacturer, and consequentially, were not enough to reassure space operators about the reliability of new, unfamiliar technologies without standardization.

In repeatedly hearing from customers that the industry needed a QML standard for plastic packaging, our company assembled a group of more than three dozen experts from industry and standardization bodies.

Our leaders share insights about QML class P (by order in the video): first Mark Toth, Manager Applications Engineering for Space Power Products, then Jason Clark, Systems Manager for Space and Avionics, and Javier Valle, General Manager Space Power Products.

Looking further ahead with TI

Space operators can now easily transition from a radiation-tolerant electronic design using our Space Enhanced Plastic portfolio to a radiation-hardened design with our QML Class P portfolio, without any hardware change given our pin-to-pin compatibility.

TI’s QML Class P certified portfolio offers solutions across the entire spacecraft electrical power system (EPS), from solar panels all the way to point of load power supplies, and the portfolio is growing.

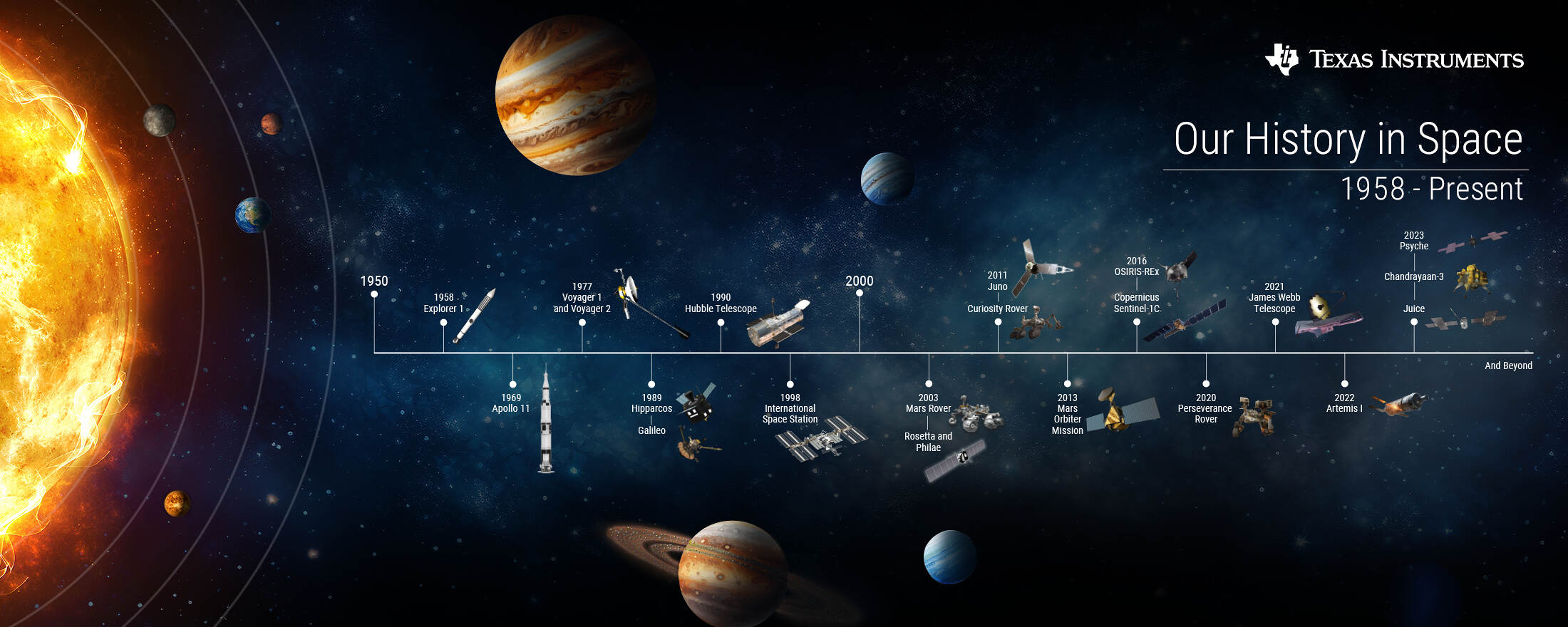

As we continue to navigate the future of space exploration, designing for space brings unlimited possibilities and solutions as endless as space itself. We have more than six decades of experience in creating solutions for space, and we look forward to helping you engineer the next frontier.